UAV Georeferencing Options

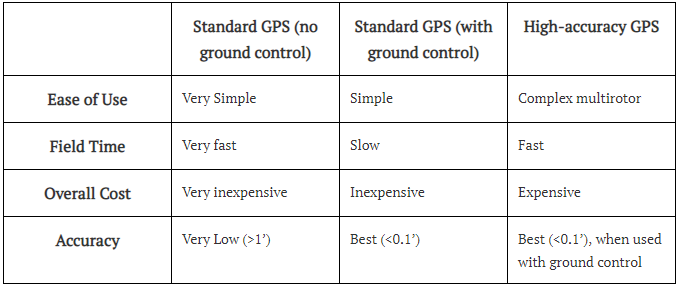

When using a drone for photogrammetry, one of the most essential data processing steps is to make sure that the orthophoto and 3D model that are produced are accurately georeferenced, so that the coordinates of any point on the model accurately match where that point exists in the real world. There are three main ways to do this: relying on the consumer-grade GPS that is standard on most drones, setting and surveying in highly accurate “ground control points” (aerial targets), or using a high-accuracy GPS system onboard the drone. Each of these has merits and drawbacks, and could be the right fit for certain survey work.

Standard GPS Without Control

Nearly any drone that a surveyor purchases has an onboard GPS system. However, unless specified, these are consumer-grade, single-band GPS receivers. Their primary function is navigation. When these drones take photos, they tag each one with a location; however, these could be off by as much as 15 feet. When these photos are stitched together, the model could, therefore, also be that inaccurate. Precision (or relative accuracy) within the model will usually be better, but could still be off by as much as a foot.

The benefit of using this standard onboard GPS is speed and simplicity. The fieldwork is minimal, requiring only to set up and fly the drone over the site – not even a GPS base station is required – and it can be done with a very inexpensive drone and a non-technical operator.

The main drawback of this approach is accuracy. It will be very rare that this approach is sufficient for a surveyor’s needs. The primary use-case would be to create a simple visual (orthophoto or web-hosted 3D model) for the sake of planning or easy reference. It may be viable for some quantity measurement projects, since absolute georeferenced accuracy is usually not needed, provided volume errors of +/-10 percent are acceptable.

Standard GPS With Ground Control

Many surveyors are already familiar with the concept of using ground control to georeference aerial data since it’s been used by conventional aerial surveyors for decades. Before flying the drone, the surveyor places a series of targets around the site and then surveys the location of those targets to very high accuracy. These targets are captured in many of the drone’s photos, allowing the photogrammetrist to input the location coordinates of the targets in the photogrammetry software, which then georeferences the entire project to the coordinate system of the ground control.

This approach provides the most consistent highest-accuracy results, usually better than 0.1 foot. It is very simple, because it does not require any new equipment and only moderate new technical capability. The targets themselves can be photo ID points, or – a solution we like a lot – checkered linoleum tiles that cost as little as $0.10 at most hardware stores. There are fewer sources of error than when relying on specialized high-accuracy onboard GPS. Another major benefit is price: ground control does not require a high-end, expensive, or complex drone.

In practice, the ease of coordinate system alignment is one of the biggest benefits of relying on ground control. Since ground control is surveyed conventionally, it is automatically in the same coordinate system as any field shots collected on the project. That means that when the photogrammetric model is georeferenced using those ground control points, the entire project automatically snaps to that coordinate system, eliminating a lot of work and headaches that can come from need to translate coordinate systems.

The main drawback of ground control is field time. The targets need to be spread evenly around the project site, meaning there is still the need for a field surveyor to spend time on the site. Given that on nearly all projects, the surveyor is going to need to walk around the site to collect boundary information and specific field-shots, the added time and effort of ground control is not too cumbersome on most projects. Though the techniques for surveying ground control targets does not require new skills, the best practices in getting the ideal number and distribution does require a lot of know-how and should be informed by comprehensive Standard Operating Procedures, training, and support.

In our experience, setting ground control is usually the best approach for most survey work. Since it requires the best and most reliable accuracy with a minimum of new equipment or skills, it is usually the ideal for most surveyors.

High-Accuracy Onboard GPS

Some boutique manufacturers offer drones that have survey-grade dual-band GPS receivers onboard, either RTK or PPK. By referencing a GPS base station or network correction data, the photos can be tagged with an extremely accurate location. There are also some manufacturers that include high-accuracy IMUs (inertial measurement units, or accelerometers), which can be integrated for an additional layer of location data – sometimes called direct georeferencing. The RTK/PPK GPS receivers record their accurate location along with time stamps constantly during the flight, so when the photos are processed, the location of each photo can be pulled from the GPS by matching time-stamps.

The main benefit of using RTK/PPK is that it reduces the amount of ground control needed. By having highly accurate photo locations, more photos can be “bridged” between ground control targets, meaning the distance between targets can be stretched, reducing the required density of targets. As a very rough rule of thumb, a good RTK/PPK system with a dialed-in workflow could reduce required number of targets by a quarter, compared to a standard GPS drone, though a minimum quantity is still required for calibration and QA/QC. On very large projects, this can translate to substantial field-time savings.

The main drawbacks are cost and complexity. Whereas a very inexpensive drone can be used with ground control to get 0.1 foot accuracy, a good RTK/PPK drone will often cost $20,000 at minimum, and easily up to $70,000. Using RTK, PPK, or DG on a drone requires a very complex combination of systems and data. The onboard GPS and/or IMU must be very precisely timed to the camera shutter, then the photos must be matched to the individual locations in post-processing. The coordinate systems then have to be matched to ensure the drone data matches ground-shots. The complexity and work involved in matching coordinate systems alone cannot be overstated: while it is certainly achievable, it adds a substantial amount of work and room for error in the data processing. Getting to 0.1 foot accuracy is doable but requires considerably more work than relying exclusively on ground control.

For particularly large projects, or on sites where fieldwork is challenging (unstable slopes after a mudslide, for example), and for teams with significant drone experience, a high-accuracy onboard GPS may be a good fit. For most survey work, though, it is more complex and expensive.

Choosing the right tool

There is no one right choice that applies to 100 percent of surveys. For projects that just need a quick and easy visual, relying on an inexpensive drone’s onboard GPS will provide most of the benefit at the least time and cost. For firms that frequently do very large or inaccessible projects, and very experienced drone-surveyors, a drone with high-accuracy GPS may be a good investment. For most survey projects and most surveyors, using an inexpensive drone with ground control, and following thorough best practices and Standard Operating Procedures for ground control target distribution will deliver the best accuracy and return on investment.